Bonded Seals

Bonded Seals (also known as Dowty Seals or Usit Rings) are static seals designed for sealing flange connections, bolt heads, hydraulic lines, threaded fittings, and cap or plug nuts.

Using Bonded Seals helps prevent the leakage of gases or liquids in your application.

They are commonly used in hydraulic systems, particularly in applications where sealing a bolt head is required.

Thanks to their metal outer ring, Bonded Seals are highly suitable for high-pressure systems.

Materials

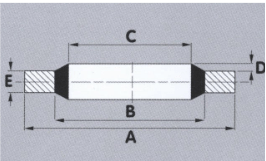

A Bonded Seal consists of a metal outer ring with a vulcanized trapezoidal sealing ring on the inside.

The choice of material depends on your specific application. What medium and temperature will it encounter?

Additionally, factors such as pressure and duration must also be considered. For a Bonded Seal, the metal ring always determines the maximum pressure the product can withstand.

The most common materials used for Bonded Seals are stainless steel and carbon steel, with elastomers such as NBR and Viton (FPM, FKM).

Metal Materials

Steel (CR6-free galvanized), Stainless Steel 304, and Stainless Steel 316, as well as zinc-chromium plated options.

Elastomer Materials

NBR, Viton (FPM, FKM), EPDM, Silicone (VMQ), FVMQ, HNBR, EPDM, and CR.

Additionally, materials are available with certifications such as KTW, WRC, NSF, WRAS, ACN, FDA, and R67 01 LPG GAS.

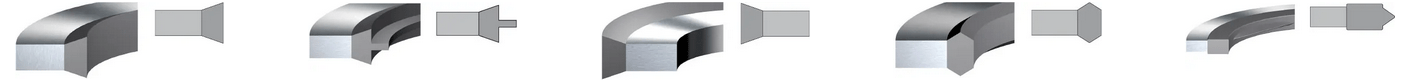

Variants

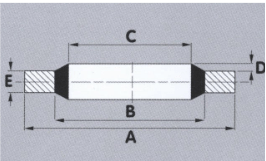

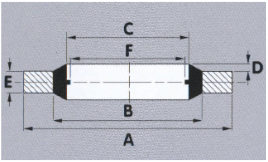

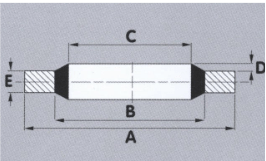

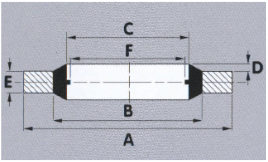

Bonded Seals are available in various designs:

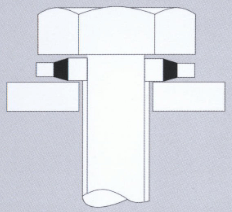

The most common types are without centering and with centering.

A Bonded Seal with centering offers several advantages. The centering feature keeps the Bonded Seal or Usit Ring (Multi Seal) securely fixed to the bolt or fitting.

This makes it ideal during assembly and disassembly.

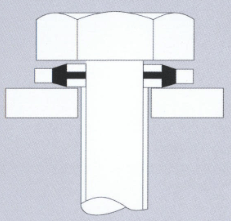

Dimensions

The size of a Bonded Seal depends on the dimensions of the nut, bolt, screw, or flange you wish to seal.

The standard sizing of the Bonded Seal corresponds to the standard sizing of the bolt, nut, screw, or flange.

You can also select the Bonded Seal based on metric measurements.

Dimensions in Inch / BSP

Including but not limited to: 5/8 – 11/16 – 1/8 – 1/4 – 3/8 – 1/2 – 5/8 – 5/ 16 – 7/16 – 9/16 – 11/16 – 15/16 – 3/4 – 7/8 – 1 – 1 1/16 – 1 3/16 – 1 5/16 – 1 1/4 – 1 1/8 – 1 1/2 – 1 3/8 – 1 5/8 – 1 7/8 – 1 3/4 – 2 – 2 1/8 – 2 1/4 – 2 1/2

Dimensions in Metric (M)

Onder andere: M3 – M4 – M5 – M6 -M8 – M10 – M11- M12 – M13 – M14 – M15 – M16 – M17 – M18 – M20 – M21 – M22 – M24 – M26 – M27 – M28 – M30 – M33 – M36 – M40

Type Bonded Seals, Usitringen, Multiseals : SC, US, USS, SES, SCR, BS, TT, TM,

Size Charts

IMPERIAL BONDED SEALS

| INDUSTRY REFERENCE | SIZE REF. | THREAD | A | B | C | D | E | F | MIN. BURST PRESSURE (BAR) | |

| BSP | BOLT | +0,13 | +0,10 | +0,10 | +0,15 | +0,20 | ||||

| -0.00 | -0.10 | -0.10 | -0.15 | -0.20 | ||||||

| PP45-1 | 1 | – | 6BA | 6,35 | 4,09 | 3,05 |

0.20/ 0.45 |

1,22 |

– | 2150 |

| PP45-2 | 2 | – | 4BA | 7,26 | 5,26 | 4,12 | – | 1570 | ||

| PP45-3 | 3 | – | 2BA | 8,38 | 6,35 | 5,21 | – | 1375 | ||

| PP45-4 | 4 | – | 1/4 | 13,21 | 8 | 6,86 | 4,7 | 2450 | ||

| PP45-5 | 5 | – | 1/4 | 13,34 | 9,53 | 6,99 | 4,7 | 1700 | ||

| PP45-6 | 6 | – | 5/16 | 13,34 | 9,53 | 8,31 | 6,1 | 1700 | ||

| PP45-7 | 7 | – | 5/16 | 14,22 | 10,04 | 8,64 | 6,1 | 1750 | ||

| PP45-A | 20 | 1/8 | 3/8 | 15,88 | 11,84 | 10,37 |

0.25/ 0.51 |

2,03 |

8,56 | 1500 |

| PP45-8 | 8 | – | 0,4 | 18,36 | 12,45 | 11,26 | 8,56 | 1950 | ||

| PP45-9 | 9 | – | 7/16 | 19,05 | 13,08 | 11,69 | 8,8 | 1900 | ||

| PP45-B | 21 | 1/4 | 1/2 | 20,57 | 15,21 | 13,74 | 11,45 | 1550 | ||

| PP45-10 | 10 | – | 9/16 | 22,23 | 16,39 | 14,86 | 11,58 | 1575 | ||

| PP45-BB | 22 | – | 0,6 | 22,23 | 17,3 | 15,83 | 12,1 | 1310 | ||

| PP45-11 | 11 | – | 5/8 | 25,4 | 18,75 | 16,51 | 12,9 | 1550 | ||

| PP45-C | 23 | 3/8 | – | 23,8 | 18,75 | 17,28 | 14,96 | 1260 | ||

| PP45-12 | 12 | – | 11/16 | 25,4 | 19,69 | 18,16 |

2,5 |

14,5 | 1320 | |

| PP45-CC | 24 | – | 3/4 | 26,92 | 21,21 | 19,69 | 15,8 | 1260 | ||

| PP45-D | 25 | 1/2 | 13/16 | 28,58 | 23,01 | 21,54 | 18,64 | 1150 | ||

| PP45-E | 26 | 5/8 | 7/8 | 31,75 | 24,97 | 23,49 | 20,6 | 1250 | ||

| PP45-13 | 13 | – | 15/16 | 33,27 | 26,04 | 24,26 | 20,2 | 1275 | ||

| PP45-F | 27 | 3/4 | 1 | 34,93 | 28,53 | 27,05 | 24,13 | 1060 | ||

| PP45-FF | 28 | – | 1.1/16 | 38,61 | 30,61 | 27,82 | 22,9 | 1250 | ||

| PP45-14 | 14 | – | 1.1/8 | 36,58 | 30,86 | 29,33 | 23,9 | 900 | ||

| PP45-HH | 31 | 1 | 1.5/16 | 42,8 | 36,88 | 33,89 | 30,3 | 810 | ||

| PP45-G | 29 | 7/8 | 1.3/16 | 38,1 | 32,29 | 30,81 | 27,89 | 900 | ||

| PP45-15 | 15 | – | 1.1/4 | 41,4 | 35,69 | 32,64 |

3,38 |

27,1 | 800 | |

| PP45-H | 30 | 1 | 1.5/16 | 42,8 | 36,88 | 33,89 | 30,3 | 810 | ||

| PP45-16 | 16 | – | 1.3/8 | 44,45 | 38,99 | 35,94 | 29,5 | 700 | ||

| PP45-17 | 17 | – | 1.1/2 | 47,75 | 42,04 | 38,96 | 32,7 | 700 | ||

| PP45-J | 32 | 1.1/4 | 1.5/8 | 52,38 | 45,93 | 42,93 | 38,96 | 690 | ||

| PP45-18 | 18 | – | 1.3/4 | 57,15 | 48,39 | 45,34 | 37,9 | 875 | ||

| PP45-K | 33 | 1.1/2 | 1.7/8 | 58,6 | 51,39 | 48,44 | 44,86 | 690 | ||

| PP45-19 | 19 | – | 2 | 63,5 | 54,74 | 51,69 | 43,6 | 780 | ||

| PP45-L | 34 | 1.3/4 | 2.1/8 | 69,85 | 58,3 | 54,89 | 50,8 | 950 | ||

| PP45-M | 36 | 2 | – | 73,03 | 63,63 | 60,58 | 56,67 | 700 | ||

| PP45-MM | 37 | – | 2.1/2 | 77,72 | 67,44 | 64,39 | 55,4 | 750 | ||

| PP45-N | 38 | 2.1/4 | – | 79,5 | 69,98 | 66,68 | 62,8 | 670 | ||

| PP45-P | 39 | 2.1/2 | – | 90,17 | 79,38 | 76,08 | 72,2 | 680 | ||

| – | 79 | 3 | – | 101,47 | 92,84 | 89,09 | 85 | 550 | ||

| PP45-H | 9030 | 1 | – | 42,8 | 36,88 | 33,89 |

0.25/ 0.51 |

2,5 |

30,3 | 810 |

| PP45-J | 9032 | 1.1/4 | – | 52,38 | 45,93 | 42,93 | 38,96 | 690 | ||

| PP45-K | 9033 | 1.1/2 | – | 58,6 | 51,39 | 48,44 | 44,86 | 690 | ||

| PP45-M | 9036 | 2 | – | 73,03 | 63,63 | 60,58 | 56,67 | 700 | ||

GERMAN METRIC BONDED SEALS

| UNDUSTRY REFERENCE | SIZE REF. | A | B | C | D | E | F | MIN. BURST PRESSURE (BAR) |

| +0,13 | +0,10 | +0,10 | +0,25 | +0,10 | +0,20 | |||

| -0.00 | -0,10 | -0,10 | -0.00 | -0,10 | -0,20 | |||

| PPM4 | 202 | 7,00 | 5,40 | 4,50 |

0,30 |

1,00 |

3,40 | 1250 |

| PPM5 | 203 | 9,00 | 6,80 | 5,70 | 4,50 | 1400 | ||

| PPM5 | 204 | 10,00 | 7,40 | 5,70 | 4,50 | 1500 | ||

| PPM5.5 | 205 | 9,20 | 7,20 | 6,20 | 4,70 | 1220 | ||

| PPM6 | 206 | 10,00 | 8,00 | 6,70 | 4,70 | 1130 | ||

| PPM6 | 207 | 11,00 | 8,20 | 6,70 | 4,70 | 1510 | ||

| PPM6.7 | 210 | 10,20 | 8,60 | 7,30 | 5,77 | 1330 | ||

| PPM8 | 212 | 13,00 | 10,00 | 8,70 | 6,40 | 1330 | ||

| PPM8 | 213 | 14,00 | 10,40 | 8,70 | 6,40 | 1550 | ||

| PPM8.5 | 215 | 13,30 | 10,50 | 9,30 | 6,90 | 1200 | ||

| PPM10 | 216 | 15,88 | 12,00 | 10,35 | 0.40

0.40 |

2,00 | 8,56 | 1450 |

| PPM10 | 217 | 16,00 | 12,40 | 10,70 |

1,50 |

8,05 | 1350 | |

| PPM10 | 218 | 18,00 | 12,40 | 10,70 | 8,05 | 1880 | ||

| PPM11 | 219 | 16,30 | 12,70 | 11,40 | 9,80 | 1250 | ||

| PPM11 | 221 | 19,10 | 13,50 | 11,80 | 9,80 | 1770 | ||

| PPM12 | 222 | 18,00 | 14,30 | 12,70 | 9,73 | 1250 | ||

| PPM12 | 223 | 20,00 | 14,40 | 12,70 | 9,73 | 1680 | ||

| PPM13 | 225 | 22,00 | 15,40 | 13,70 | 10,80 | 1810 | ||

| PPM13.5 | 226 | 18,70 | 15,70 | 14,00 | 11,30 | 900 | ||

| PPM14 | 227 | 22,00 | 16,40 | 14,70 | 11,38 | 1510 | ||

| PPM16 | 229 | 24,00 | 18,40 | 16,70 | 13,41 | 1400 | ||

| PPM17 | 230 | 24,00 | 19,20 | 17,40 | 13,08 | 1150 | ||

| PPM17.5 | 231 | 24,70 | 20,10 | 18,00 | 13,60 | 1070 | ||

| PPM18 | 232 | 26,00 | 20,40 | 18,70 | 14,76 | 1275 | ||

| PPM20 | 233 | 28,00 | 22,50 | 20,70 | 16,76 | 1150 | ||

| PPM21 | 234 | 28,70 | 23,30 | 21,50 | 2,50 | 17,80 | 1080 | |

| PPM22 | 235 | 28,00 | 24,20 | 22,50 | 1,50 | 18,10 | 760 | |

| PPM22 | 236 | 30,00 | 24,40 | 22,70 | 2,00 | 18,74 | 1100 | |

| PPM22 | 237 | 30,00 | 24,40 | 22,70 | 3,00 | 18,74 | 1080 | |

| PPM24 | 238 | 32,00 | 26,40 | 24,70 |

2,00 |

20,11 | 1050 | |

| PPM26 | 239 | 35,00 | 28,40 | 26,70 | 22,30 | 1050 | ||

| PPM27 | 240 | 36,00 | 29,00 | 27,20 | 23,30 | 1130 | ||

| PPM30 | 242 | 39,00 | 33,00 | 31,00 | 25,70 | 860 | ||

| PPM33 | 243 | 42,00 | 35,80 | 33,70 | 28,70 | 900 | ||

| PPM33 | 244 | 43,00 | 36,40 | 34,30 | 28,70 | 880 | ||

| PPM36 | 245 | 46,00 | 38,80 | 36,70 | 31,10 | 880 | ||

| PPM39 | 246 | 51,00 | 41,90 | 40,00 | 2,50 | 34,10 | 1020 | |

| PPM42 | 247 | 53,00 | 44,40 | 42,70 |

3,00 |

36,50 | 940 | |

| PPM48 | 248 | 59,00 | 50,80 | 48,70 | 41,90 | 800 | ||

| PPM52 | 250 | 64,50 | 56,40 | 53,30 | – | 710 | ||

| PPM88 | 254 | 101,35 | 92,10 | 89,09 | 3,25 | – | 510 |

FRENCH METRIC BONDED SEALS

| PAMARGAN REFERENCE | ALTERNATIVE REF. | A | B | C | D | E | F | MIN. BURST PRESSURE (BAR) |

| +0,13 | +0,10 | +0,10 | +0,25 | +0,10 | +0,20 | |||

| -0.00 | -0,10 | -0,10 | -0.00 | -0,10 | -0,20 | |||

| PPFM3 | 301 | 7,50 | 5,00 | 3,60 |

0,30 |

1,00 |

– | 1950 |

| PPFM4 | 302 | 9,00 | 6,00 | 4,60 | 3,40 | 2000 | ||

| PPFM5 | 303 | 10,00 | 7,00 | 5,60 | 4,50 | 1780 | ||

| PPFM6 | 304 | 11,00 | 8,00 | 6,60 | 4,70 | 1680 | ||

| PPFM6 | 306 | 11,40 | 8,40 | 7,00 | 4,70 | 1540 | ||

| PPFM8 | 307 | 13,00 | 10,00 | 8,60 | 6,40 | 1330 | ||

| PPFM10 | 310 | 17,00 | 12,10 | 10,70 |

1,50 |

8,56 | 1730 | |

| PPFM11 | 312 | 18,10 | 13,20 | 11,80 | 9,80 | 1600 | ||

| PPFM12 | 313 | 19,00 | 14,10 | 12,70 | 9,73 | 1530 | ||

| PPFM13 | 315 | 20,10 | 15,20 | 13,80 | 0,40 | 10,80 | 1440 | |

| PPFM14 | 316 | 21,00 | 16,10 | 14,70 | 0,30 | 11,38 | 1370 | |

| PPFM16 | 317 | 23,00 | 18,10 | 16,70 | 13,41 | 1240 | ||

| PPFM17 | 318 | 23,70 | 18,80 | 17,40 | 0,40 | 13,08 | 1200 | |

| PPFM18 | 320 | 27,00 | 20,40 | 18,70 | 0,30 |

2,00 |

14,76 | 1450 |

| PPFM20 | 321 | 29,00 | 22,40 | 20,70 | 16,76 | 1340 | ||

| PPFM21 | 323 | 30,00 | 23,40 | 21,70 |

0,40 |

17,80 | 1290 | |

| PPFM22 | 324 | 31,00 | 24,40 | 22,70 | 18,74 | 1240 | ||

| PPFM23 | 325 | 32,00 | 25,40 | 23,70 | 19,30 | 960 | ||

| PPFM24 | 326 | 33,00 | 26,40 | 24,70 | 20,11 | 1160 | ||

| PPFM26 | 327 | 35,30 | 28,70 | 27,00 | 22,30 | 870 | ||

| PPFM27 | 328 | 36,00 | 29,40 | 27,70 | 23,30 | 1060 | ||

| PPFM28 | 329 | 36,00 | 30,30 | 28,60 | 24,80 | 730 | ||

| PPFM30 | 331 | 39,00 | 32,40 | 30,70 | 25,70 | 970 | ||

| PPFM33 | 332 | 42,00 | 35,40 | 33,70 | 28,70 | 900 | ||

| PPFM36 | 333 | 48,00 | 39,60 | 37,00 |

2.50 |

31,10 | 1010 | |

| PPFM39 | 334 | 51,00 | 42,60 | 40,00 | 34,10 | 950 | ||

| PPFM42 | 335 | 54,00 | 45,60 | 43,00 | 36,50 | 890 | ||

| PPFM45 | 336 | 57,00 | 48,60 | 46,00 | 39,50 | 860 | ||

| PPFM48 | 337 | 60,00 | 51,60 | 49,00 | 41,90 | 790 |

Rubber Compatibility

| NITRILE (NBR) |

HYDROGENATED NITRILE (HNBR) |

FLUOROCARBON (FKM) |

SILICONE (VMQ) | FLUOROSILICONE (FVMQ) | ETHYLENE PROPYLENE (EPDM) | CHLOROPRENE (CR) | |

| General Characteristics | |||||||

| Hardness range IRHD | 40-90 | 40-85 | 60-90 | 40-80 | 40-80 | 80-90 | 40-80 |

| Continuous high temperature limit | 100∞C | 135∞C | 200∞C | 200∞C | 175∞C | 125∞C | 140∞C |

| Low temperature capability | -30∞C | -40∞C | -25∞C | -60∞C | -60∞C | -30∞C | -55∞C |

| Dynamic service/Abrasion resistance | Excellent | Excellent | Very Good | Poor | Poor | Fair | Very Good |

| Compression set resistance | Very Good | Excellent | Very Good | Excellent | Very Good | Very Good | Good |

| Fluid Compatibility | |||||||

| Acid Inorganic | Fair | Good | Good | Good | Good | Excellent | Fair/Good |

| Acid Organic | Good | Good | Good | Excellent | Good | Good | Good |

| Ageing Oxygen | Fair | Good | Very Good | Excellent | Excellent | Excellent | Very Good |

| Ageing Ozone | Fair/Poor | Good | Very Good | Excellent | Excellent | Excellent | Very Good |

| Ageing Weather | Poor | Good | Very Good | Excellent | Excellent | Excellent | Very Good |

| Air | Fair | Excellent | Very Good | Excellent | Very Good | Excellent | Good |

| Alcohols | Very Good | Excellent | Fair | Very Good | Very Good | Very Good | Very Good |

| Aldehydes | Fair/Poor | Fair | Poor | Good | Poor | Very Good | Fair/Poor |

| Alkalis | Fair/Poor | Fair | Good | Very Good | Good | Very Good | Good |

| Amines | Poor | Poor | Poor | Good | Poor | Good | Very Good |

| Animal oils | Excellent | Excellent | Very Good | Good | Excellent | Very Good | Good |

| Esters Alkyl Phosphate (Skydrol) | Poor | Poor | Poor | Good | Fair/Poor | Fair/Good | Poor |

| Esters Aryl Phosphate | Fair/Poor | Fair | Excellent | Good | Very Good | Fair | Fair/Poor |

| Esters Silicate | Good | Good | Excellent | Poor | Very Good | Fair | Fair |

| Ethers | Poor | Poor | Poor | Poor | Fair | Poor | Poor |

| Gas permeability | Good | Good/Excellent | Good | Poor | Poor | Good | Good |

| Hydrocarbon fuels Aliphatic | Excellent | Excellent | Excellent | Fair | Excellent | Poor | Fair |

| Hydrocarbon fuels Aromatic | Good | Good | Excellent | Poor | Very Good | Poor | Fair/Poor |

| Hydrocarbons Halogenated | Fair/Poor | Poor | Excellent | Poor | Very Good | Good | Poor |

| Ketones | Poor | Poor | Poor | Poor | Fair/Poor | Very Good | Poor |

| Lubricating oils High aniline | Excellent | Excellent | Excellent | Very Good | Very Good | Poor | Good |

| Lubricating oils Low aniline | Very Good | Excellent | Excellent | Fair | Poor | Poor | Fair/Poor |

| Silicone oils | Excellent | Excellent | Excellent | Good | Excellent | Very Good | Excellent |

| Vegetable oils | Excellent | Excellent | Excellent | Excellent | Excellent | Very Good | Good |

| Water/steam | Good/Excellent | Excellent | Fair | Fair | Fair | Excellent | Fair |

Other Types of Usit Rings / Washers

Including Parker fitting seals, Stat-O-Seal, Thread Seal, UNC, UNF, 600, 610, 750, and 800.

Manufacturers of Bonded Seals, Usit Rings, Multiseals, Multi-Seals, Dowty Seals, Dyna Seals, Mega Rings, and Washers

Trelleborg (Busak+Shamban), Dowty, Parker, Dichtomatik, Eriks Merkel, NAK, and NOK.

Order your Bonded Seals directly at our webshop.