Bonded Seals

Bonded Seals (ook wel bekend als Dowty Seals of Usit ringen) zijn statische afdichtingen voor het afdichten van flensverbindingen van boutkoppen, hydraulische leidingen, schroefkoppelingen en sluit en dop moeren.

Door het gebruiken van Bonded Seals voorkom je lekkage van gassen of vloeistoffen in uw toepassing.

Bonded Seals word over het algemeen veel gebruikt in hydraulische systemen. hier worden ze vaak toegepast in een toepassing waar je een boutkop moet afdichten.

Bonded seals zijn, vanwege de metalen buitenring, zeer geschikt voor hoge druk systemen.

Materialen

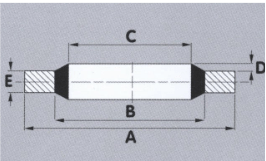

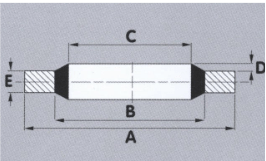

Een Bonded Seal heeft een metalen buitenring met aan de binnenzijde gevulkaniseerde trapeziumvormige afdichtingsring.

Welk materiaal er gebruikt moet worden hangt af van uw toepassing. Met welk medium en temperatuur komt het in aanraking?

Daarbij moet er ook rekening gehouden worden met de druk en tijd. Bij een Bonded Seal bepaalt de metalen ring altijd de maximale druk die het product aankan.

Het meest voorkomende materiaal bij Bonded Seals is RVS en Staal, met als elasomeren NBR en Viton (FPM, FKM).

Materialen metaal:

Staal verzinkt CR6 vrij, RVS 304 en RVS 316 Stainless Steel, zink verchroomd

Materialen elastomeren:

NBR, Viton (FPM, FKM), Epdm, Silicone (VMQ) , FVMQ, HNBR, EPDM, CR.

Tevens met toelatingen als KTW, WRC, NSF, WRAS, ACN en FDA, R67 01 LPG GAS.

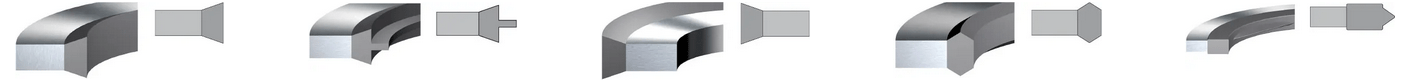

Uitvoeringen

Een Bonded Seal is leverbaar in meerdere uitvoeringen:

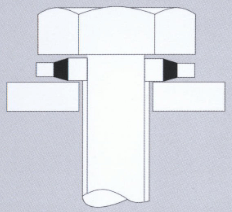

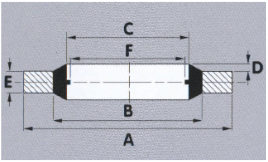

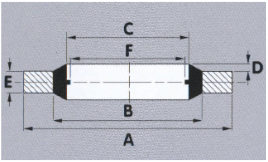

De bekendste zijn de zonder centrering en met centrering.

Een Bonded Seal met centrering heeft zijn voordelen. Met centrering blijft de bonded seal / usitring Multi Seal gefixeerd op de bout of koppeling zitten.

Ideaal dus op moment van montage en demontage.

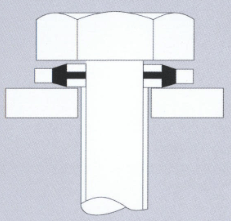

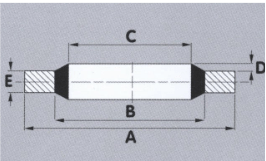

Afmetingen

De maat/afmeting van een Bonded Seal is afhankelijk van de afmetingen van de moer, schroef, Bout of flens die u wilt afdichten.

De normering van de Bonded Seal is dan gelijk aan de normering van de bout, moer, schroef of flens.

U kunt de Bonded Seal ook selecteren op metrische maten.

Afmetingen Inch / BSP

Onder andere: 5/8 – 11/16 – 1/8 – 1/4 – 3/8 – 1/2 – 5/8 – 5/ 16 – 7/16 – 9/16 – 11/16 – 15/16 – 3/4 – 7/8 – 1 – 1 1/16 – 1 3/16 – 1 5/16 – 1 1/4 – 1 1/8 – 1 1/2 – 1 3/8 – 1 5/8 – 1 7/8 – 1 3/4 – 2 – 2 1/8 – 2 1/4 – 2 1/2

Afmetingen M Metrich

Onder andere: M3 – M4 – M5 – M6 -M8 – M10 – M11- M12 – M13 – M14 – M15 – M16 – M17 – M18 – M20 – M21 – M22 – M24 – M26 – M27 – M28 – M30 – M33 – M36 – M40

Type Bonded Seals, Usitringen, Multiseals : SC, US, USS, SES, SCR, BS, TT, TM,

Matenlijsten

IMPERIAL BONDED SEALS

| INDUSTRY REFERENCE | SIZE REF. | THREAD | A | B | C | D | E | F | MIN. BURST PRESSURE (BAR) | |

| BSP | BOLT | +0,13 | +0,10 | +0,10 | +0,15 | +0,20 | ||||

| -0.00 | -0.10 | -0.10 | -0.15 | -0.20 | ||||||

| PP45-1 | 1 | – | 6BA | 6,35 | 4,09 | 3,05 |

0.20/ 0.45 |

1,22 |

– | 2150 |

| PP45-2 | 2 | – | 4BA | 7,26 | 5,26 | 4,12 | – | 1570 | ||

| PP45-3 | 3 | – | 2BA | 8,38 | 6,35 | 5,21 | – | 1375 | ||

| PP45-4 | 4 | – | 1/4 | 13,21 | 8 | 6,86 | 4,7 | 2450 | ||

| PP45-5 | 5 | – | 1/4 | 13,34 | 9,53 | 6,99 | 4,7 | 1700 | ||

| PP45-6 | 6 | – | 5/16 | 13,34 | 9,53 | 8,31 | 6,1 | 1700 | ||

| PP45-7 | 7 | – | 5/16 | 14,22 | 10,04 | 8,64 | 6,1 | 1750 | ||

| PP45-A | 20 | 1/8 | 3/8 | 15,88 | 11,84 | 10,37 |

0.25/ 0.51 |

2,03 |

8,56 | 1500 |

| PP45-8 | 8 | – | 0,4 | 18,36 | 12,45 | 11,26 | 8,56 | 1950 | ||

| PP45-9 | 9 | – | 7/16 | 19,05 | 13,08 | 11,69 | 8,8 | 1900 | ||

| PP45-B | 21 | 1/4 | 1/2 | 20,57 | 15,21 | 13,74 | 11,45 | 1550 | ||

| PP45-10 | 10 | – | 9/16 | 22,23 | 16,39 | 14,86 | 11,58 | 1575 | ||

| PP45-BB | 22 | – | 0,6 | 22,23 | 17,3 | 15,83 | 12,1 | 1310 | ||

| PP45-11 | 11 | – | 5/8 | 25,4 | 18,75 | 16,51 | 12,9 | 1550 | ||

| PP45-C | 23 | 3/8 | – | 23,8 | 18,75 | 17,28 | 14,96 | 1260 | ||

| PP45-12 | 12 | – | 11/16 | 25,4 | 19,69 | 18,16 |

2,5 |

14,5 | 1320 | |

| PP45-CC | 24 | – | 3/4 | 26,92 | 21,21 | 19,69 | 15,8 | 1260 | ||

| PP45-D | 25 | 1/2 | 13/16 | 28,58 | 23,01 | 21,54 | 18,64 | 1150 | ||

| PP45-E | 26 | 5/8 | 7/8 | 31,75 | 24,97 | 23,49 | 20,6 | 1250 | ||

| PP45-13 | 13 | – | 15/16 | 33,27 | 26,04 | 24,26 | 20,2 | 1275 | ||

| PP45-F | 27 | 3/4 | 1 | 34,93 | 28,53 | 27,05 | 24,13 | 1060 | ||

| PP45-FF | 28 | – | 1.1/16 | 38,61 | 30,61 | 27,82 | 22,9 | 1250 | ||

| PP45-14 | 14 | – | 1.1/8 | 36,58 | 30,86 | 29,33 | 23,9 | 900 | ||

| PP45-HH | 31 | 1 | 1.5/16 | 42,8 | 36,88 | 33,89 | 30,3 | 810 | ||

| PP45-G | 29 | 7/8 | 1.3/16 | 38,1 | 32,29 | 30,81 | 27,89 | 900 | ||

| PP45-15 | 15 | – | 1.1/4 | 41,4 | 35,69 | 32,64 |

3,38 |

27,1 | 800 | |

| PP45-H | 30 | 1 | 1.5/16 | 42,8 | 36,88 | 33,89 | 30,3 | 810 | ||

| PP45-16 | 16 | – | 1.3/8 | 44,45 | 38,99 | 35,94 | 29,5 | 700 | ||

| PP45-17 | 17 | – | 1.1/2 | 47,75 | 42,04 | 38,96 | 32,7 | 700 | ||

| PP45-J | 32 | 1.1/4 | 1.5/8 | 52,38 | 45,93 | 42,93 | 38,96 | 690 | ||

| PP45-18 | 18 | – | 1.3/4 | 57,15 | 48,39 | 45,34 | 37,9 | 875 | ||

| PP45-K | 33 | 1.1/2 | 1.7/8 | 58,6 | 51,39 | 48,44 | 44,86 | 690 | ||

| PP45-19 | 19 | – | 2 | 63,5 | 54,74 | 51,69 | 43,6 | 780 | ||

| PP45-L | 34 | 1.3/4 | 2.1/8 | 69,85 | 58,3 | 54,89 | 50,8 | 950 | ||

| PP45-M | 36 | 2 | – | 73,03 | 63,63 | 60,58 | 56,67 | 700 | ||

| PP45-MM | 37 | – | 2.1/2 | 77,72 | 67,44 | 64,39 | 55,4 | 750 | ||

| PP45-N | 38 | 2.1/4 | – | 79,5 | 69,98 | 66,68 | 62,8 | 670 | ||

| PP45-P | 39 | 2.1/2 | – | 90,17 | 79,38 | 76,08 | 72,2 | 680 | ||

| – | 79 | 3 | – | 101,47 | 92,84 | 89,09 | 85 | 550 | ||

| PP45-H | 9030 | 1 | – | 42,8 | 36,88 | 33,89 |

0.25/ 0.51 |

2,5 |

30,3 | 810 |

| PP45-J | 9032 | 1.1/4 | – | 52,38 | 45,93 | 42,93 | 38,96 | 690 | ||

| PP45-K | 9033 | 1.1/2 | – | 58,6 | 51,39 | 48,44 | 44,86 | 690 | ||

| PP45-M | 9036 | 2 | – | 73,03 | 63,63 | 60,58 | 56,67 | 700 | ||

GERMAN METRIC BONDED SEALS

| UNDUSTRY REFERENCE | SIZE REF. | A | B | C | D | E | F | MIN. BURST PRESSURE (BAR) |

| +0,13 | +0,10 | +0,10 | +0,25 | +0,10 | +0,20 | |||

| -0.00 | -0,10 | -0,10 | -0.00 | -0,10 | -0,20 | |||

| PPM4 | 202 | 7,00 | 5,40 | 4,50 |

0,30 |

1,00 |

3,40 | 1250 |

| PPM5 | 203 | 9,00 | 6,80 | 5,70 | 4,50 | 1400 | ||

| PPM5 | 204 | 10,00 | 7,40 | 5,70 | 4,50 | 1500 | ||

| PPM5.5 | 205 | 9,20 | 7,20 | 6,20 | 4,70 | 1220 | ||

| PPM6 | 206 | 10,00 | 8,00 | 6,70 | 4,70 | 1130 | ||

| PPM6 | 207 | 11,00 | 8,20 | 6,70 | 4,70 | 1510 | ||

| PPM6.7 | 210 | 10,20 | 8,60 | 7,30 | 5,77 | 1330 | ||

| PPM8 | 212 | 13,00 | 10,00 | 8,70 | 6,40 | 1330 | ||

| PPM8 | 213 | 14,00 | 10,40 | 8,70 | 6,40 | 1550 | ||

| PPM8.5 | 215 | 13,30 | 10,50 | 9,30 | 6,90 | 1200 | ||

| PPM10 | 216 | 15,88 | 12,00 | 10,35 |

0.40

0.40 |

2,00 | 8,56 | 1450 |

| PPM10 | 217 | 16,00 | 12,40 | 10,70 |

1,50 |

8,05 | 1350 | |

| PPM10 | 218 | 18,00 | 12,40 | 10,70 | 8,05 | 1880 | ||

| PPM11 | 219 | 16,30 | 12,70 | 11,40 | 9,80 | 1250 | ||

| PPM11 | 221 | 19,10 | 13,50 | 11,80 | 9,80 | 1770 | ||

| PPM12 | 222 | 18,00 | 14,30 | 12,70 | 9,73 | 1250 | ||

| PPM12 | 223 | 20,00 | 14,40 | 12,70 | 9,73 | 1680 | ||

| PPM13 | 225 | 22,00 | 15,40 | 13,70 | 10,80 | 1810 | ||

| PPM13.5 | 226 | 18,70 | 15,70 | 14,00 | 11,30 | 900 | ||

| PPM14 | 227 | 22,00 | 16,40 | 14,70 | 11,38 | 1510 | ||

| PPM16 | 229 | 24,00 | 18,40 | 16,70 | 13,41 | 1400 | ||

| PPM17 | 230 | 24,00 | 19,20 | 17,40 | 13,08 | 1150 | ||

| PPM17.5 | 231 | 24,70 | 20,10 | 18,00 | 13,60 | 1070 | ||

| PPM18 | 232 | 26,00 | 20,40 | 18,70 | 14,76 | 1275 | ||

| PPM20 | 233 | 28,00 | 22,50 | 20,70 | 16,76 | 1150 | ||

| PPM21 | 234 | 28,70 | 23,30 | 21,50 | 2,50 | 17,80 | 1080 | |

| PPM22 | 235 | 28,00 | 24,20 | 22,50 | 1,50 | 18,10 | 760 | |

| PPM22 | 236 | 30,00 | 24,40 | 22,70 | 2,00 | 18,74 | 1100 | |

| PPM22 | 237 | 30,00 | 24,40 | 22,70 | 3,00 | 18,74 | 1080 | |

| PPM24 | 238 | 32,00 | 26,40 | 24,70 |

2,00 |

20,11 | 1050 | |

| PPM26 | 239 | 35,00 | 28,40 | 26,70 | 22,30 | 1050 | ||

| PPM27 | 240 | 36,00 | 29,00 | 27,20 | 23,30 | 1130 | ||

| PPM30 | 242 | 39,00 | 33,00 | 31,00 | 25,70 | 860 | ||

| PPM33 | 243 | 42,00 | 35,80 | 33,70 | 28,70 | 900 | ||

| PPM33 | 244 | 43,00 | 36,40 | 34,30 | 28,70 | 880 | ||

| PPM36 | 245 | 46,00 | 38,80 | 36,70 | 31,10 | 880 | ||

| PPM39 | 246 | 51,00 | 41,90 | 40,00 | 2,50 | 34,10 | 1020 | |

| PPM42 | 247 | 53,00 | 44,40 | 42,70 |

3,00 |

36,50 | 940 | |

| PPM48 | 248 | 59,00 | 50,80 | 48,70 | 41,90 | 800 | ||

| PPM52 | 250 | 64,50 | 56,40 | 53,30 | – | 710 | ||

| PPM88 | 254 | 101,35 | 92,10 | 89,09 | 3,25 | – | 510 |

FRENCH METRIC BONDED SEALS

| PAMARGAN REFERENCE | ALTERNATIVE REF. | A | B | C | D | E | F | MIN. BURST PRESSURE (BAR) |

| +0,13 | +0,10 | +0,10 | +0,25 | +0,10 | +0,20 | |||

| -0.00 | -0,10 | -0,10 | -0.00 | -0,10 | -0,20 | |||

| PPFM3 | 301 | 7,50 | 5,00 | 3,60 |

0,30 |

1,00 |

– | 1950 |

| PPFM4 | 302 | 9,00 | 6,00 | 4,60 | 3,40 | 2000 | ||

| PPFM5 | 303 | 10,00 | 7,00 | 5,60 | 4,50 | 1780 | ||

| PPFM6 | 304 | 11,00 | 8,00 | 6,60 | 4,70 | 1680 | ||

| PPFM6 | 306 | 11,40 | 8,40 | 7,00 | 4,70 | 1540 | ||

| PPFM8 | 307 | 13,00 | 10,00 | 8,60 | 6,40 | 1330 | ||

| PPFM10 | 310 | 17,00 | 12,10 | 10,70 |

1,50 |

8,56 | 1730 | |

| PPFM11 | 312 | 18,10 | 13,20 | 11,80 | 9,80 | 1600 | ||

| PPFM12 | 313 | 19,00 | 14,10 | 12,70 | 9,73 | 1530 | ||

| PPFM13 | 315 | 20,10 | 15,20 | 13,80 | 0,40 | 10,80 | 1440 | |

| PPFM14 | 316 | 21,00 | 16,10 | 14,70 | 0,30 | 11,38 | 1370 | |

| PPFM16 | 317 | 23,00 | 18,10 | 16,70 | 13,41 | 1240 | ||

| PPFM17 | 318 | 23,70 | 18,80 | 17,40 | 0,40 | 13,08 | 1200 | |

| PPFM18 | 320 | 27,00 | 20,40 | 18,70 | 0,30 |

2,00 |

14,76 | 1450 |

| PPFM20 | 321 | 29,00 | 22,40 | 20,70 | 16,76 | 1340 | ||

| PPFM21 | 323 | 30,00 | 23,40 | 21,70 |

0,40 |

17,80 | 1290 | |

| PPFM22 | 324 | 31,00 | 24,40 | 22,70 | 18,74 | 1240 | ||

| PPFM23 | 325 | 32,00 | 25,40 | 23,70 | 19,30 | 960 | ||

| PPFM24 | 326 | 33,00 | 26,40 | 24,70 | 20,11 | 1160 | ||

| PPFM26 | 327 | 35,30 | 28,70 | 27,00 | 22,30 | 870 | ||

| PPFM27 | 328 | 36,00 | 29,40 | 27,70 | 23,30 | 1060 | ||

| PPFM28 | 329 | 36,00 | 30,30 | 28,60 | 24,80 | 730 | ||

| PPFM30 | 331 | 39,00 | 32,40 | 30,70 | 25,70 | 970 | ||

| PPFM33 | 332 | 42,00 | 35,40 | 33,70 | 28,70 | 900 | ||

| PPFM36 | 333 | 48,00 | 39,60 | 37,00 |

2.50 |

31,10 | 1010 | |

| PPFM39 | 334 | 51,00 | 42,60 | 40,00 | 34,10 | 950 | ||

| PPFM42 | 335 | 54,00 | 45,60 | 43,00 | 36,50 | 890 | ||

| PPFM45 | 336 | 57,00 | 48,60 | 46,00 | 39,50 | 860 | ||

| PPFM48 | 337 | 60,00 | 51,60 | 49,00 | 41,90 | 790 |

Rubber Compatibiliteit

| NITRILE (NBR) |

HYDROGENATED NITRILE (HNBR) |

FLUOROCARBON (FKM) |

SILICONE (VMQ) | FLUOROSILICONE (FVMQ) | ETHYLENE PROPYLENE (EPDM) | CHLOROPRENE (CR) | |

| General Characteristics | |||||||

| Hardness range IRHD | 40-90 | 40-85 | 60-90 | 40-80 | 40-80 | 80-90 | 40-80 |

| Continuous high temperature limit | 100∞C | 135∞C | 200∞C | 200∞C | 175∞C | 125∞C | 140∞C |

| Low temperature capability | -30∞C | -40∞C | -25∞C | -60∞C | -60∞C | -30∞C | -55∞C |

| Dynamic service/Abrasion resistance | Excellent | Excellent | Very Good | Poor | Poor | Fair | Very Good |

| Compression set resistance | Very Good | Excellent | Very Good | Excellent | Very Good | Very Good | Good |

| Fluid Compatibility | |||||||

| Acid Inorganic | Fair | Good | Good | Good | Good | Excellent | Fair/Good |

| Acid Organic | Good | Good | Good | Excellent | Good | Good | Good |

| Ageing Oxygen | Fair | Good | Very Good | Excellent | Excellent | Excellent | Very Good |

| Ageing Ozone | Fair/Poor | Good | Very Good | Excellent | Excellent | Excellent | Very Good |

| Ageing Weather | Poor | Good | Very Good | Excellent | Excellent | Excellent | Very Good |

| Air | Fair | Excellent | Very Good | Excellent | Very Good | Excellent | Good |

| Alcohols | Very Good | Excellent | Fair | Very Good | Very Good | Very Good | Very Good |

| Aldehydes | Fair/Poor | Fair | Poor | Good | Poor | Very Good | Fair/Poor |

| Alkalis | Fair/Poor | Fair | Good | Very Good | Good | Very Good | Good |

| Amines | Poor | Poor | Poor | Good | Poor | Good | Very Good |

| Animal oils | Excellent | Excellent | Very Good | Good | Excellent | Very Good | Good |

| Esters Alkyl Phosphate (Skydrol) | Poor | Poor | Poor | Good | Fair/Poor | Fair/Good | Poor |

| Esters Aryl Phosphate | Fair/Poor | Fair | Excellent | Good | Very Good | Fair | Fair/Poor |

| Esters Silicate | Good | Good | Excellent | Poor | Very Good | Fair | Fair |

| Ethers | Poor | Poor | Poor | Poor | Fair | Poor | Poor |

| Gas permeability | Good | Good/Excellent | Good | Poor | Poor | Good | Good |

| Hydrocarbon fuels Aliphatic | Excellent | Excellent | Excellent | Fair | Excellent | Poor | Fair |

| Hydrocarbon fuels Aromatic | Good | Good | Excellent | Poor | Very Good | Poor | Fair/Poor |

| Hydrocarbons Halogenated | Fair/Poor | Poor | Excellent | Poor | Very Good | Good | Poor |

| Ketones | Poor | Poor | Poor | Poor | Fair/Poor | Very Good | Poor |

| Lubricating oils High aniline | Excellent | Excellent | Excellent | Very Good | Very Good | Poor | Good |

| Lubricating oils Low aniline | Very Good | Excellent | Excellent | Fair | Poor | Poor | Fair/Poor |

| Silicone oils | Excellent | Excellent | Excellent | Good | Excellent | Very Good | Excellent |

| Vegetable oils | Excellent | Excellent | Excellent | Excellent | Excellent | Very Good | Good |

| Water/steam | Good/Excellent | Excellent | Fair | Fair | Fair | Excellent | Fair |

Overige type Usit rings / washers; Parker fitting seals; Stat-O-Seal, Thread Seal, UNC, UNF, 600, 610, 750, 800.

Fabrikanten Bonded seal, Usit ring, Multiseal, Multi – Seal, Dowty seal, Dyna seal, Mega ring, onderlegring: Trelleborg ( busak Shamban ), Dowty, Parker, Dichtomatik, Eriks Merkel, NAK, NOK.

Bestel uw Bonded Seals direct bij onze webshop